How to Choose the Right Industrial Trolley for Your Needs?

In the fast-paced world of industrial settings,

efficiency and productivity are paramount. One often overlooked but crucial

element in achieving these goals is the industrial trolley. These versatile

tools come in various shapes and sizes, designed to meet the unique needs of

different industries. Choosing the right industrial trolleys in

Sydney for your specific requirements can significantly enhance

workflow and streamline operations. In this guide, we will explore key factors

to consider when selecting an industrial trolley to ensure it aligns perfectly

with your needs.

Understanding Your

Requirements

Before diving into the selection process, it's

essential to have a clear understanding of your specific needs. Consider the

type of materials or products you'll be transporting, the frequency of use, and

the environment in which the trolleys

Sydney will operate. Different industries have distinct demands, and

tailoring your choice to your unique requirements is the first step towards

making an informed decision.

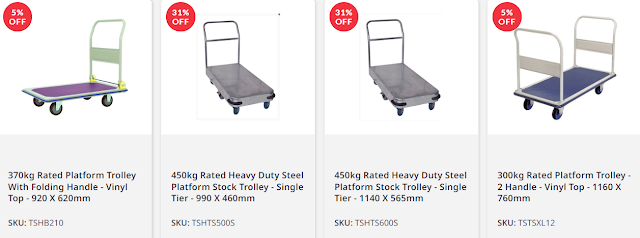

Load Capacity

One of the fundamental aspects to consider is the

load capacity of the Sydney trolleys.

Assess the maximum weight the trolley will need to carry regularly. It's

advisable to choose a trolley with a higher load capacity than you currently require

to accommodate potential future needs. This ensures longevity and prevents the

risk of overloading, which can lead to safety hazards and damage to the

trolley.

Trolley Material and

Construction

The material and construction of the trolley play a

crucial role in its durability and suitability for different environments.

Common materials include stainless steel, aluminum, and heavy-duty plastics.

Stainless steel is ideal for corrosive environments, while aluminum offers a

good balance between strength and weight. Heavy-duty plastics are suitable for

lightweight applications and environments where corrosion is not a concern.

Consider the durability required for your industry and choose a material that

aligns with those needs.

Wheel Type and Configuration

The wheels are a vital component of an industrial

trolley, affecting both maneuverability and stability. Consider the type of

flooring in your facility and choose wheels that won't cause damage. Options

include rubber, polyurethane, and pneumatic wheels, each offering unique

benefits. The configuration of the wheels, such as swivel or fixed, impacts the

trolley's ability to navigate tight spaces. A combination of swivel and fixed

wheels is often the most versatile choice.

Handle and Steering

Mechanism

The design of the handle and steering mechanism is

crucial for the operator's comfort and ease of use. Trolleys with ergonomic

handles and easy-to-use steering mechanisms contribute to a more efficient and

safer working environment. Consider options such as push handles, tow bars, or

even motorized trolleys for heavy loads that require powered assistance.

Size and Dimensions

The size and dimensions of the industrial trolley

should align with the space constraints of your facility. Consider the width of

doorways, aisle widths, and any tight corners the trolley needs to navigate.

Consider for a size that maximizes efficiency while ensuring easy

maneuverability in your specific working environment.

Additional Features and

Accessories

Depending on your industry and application, you may

require additional features or accessories. This could include shelves, bins,

or compartments for better organization, as well as braking systems for

enhanced safety during transport and storage. Evaluate the available options

and choose a trolley that can be customized to meet your specific needs.

Budget Considerations

While it's tempting to focus solely on features and

capabilities, it's essential to consider your budget constraints. Determine a

budget range based on your needs and prioritize features accordingly. Balance

the initial investment with the long-term benefits and durability of the chosen

industrial trolley.

Conclusion

Choosing the right industrial trolley is a critical decision that can impact the efficiency and

safety of your operations. By carefully considering factors such as load

capacity, material and construction, wheel type, handle design, size, and

budget constraints, you can make an informed decision that aligns with your

specific requirements. Investing time in selecting the right industrial trolley

now can lead to long-term improvements in workflow, productivity, and overall

operational success.

Comments

Post a Comment