5 Ways Industrial Trolleys Can Boost Efficiency in manufacturing industries

In the realm of manufacturing industries, efficiency

is the key to success. Every process, no matter how minor, contributes to the

overall productivity of a facility. One often-overlooked asset that can

significantly enhance efficiency is the industrial trolleys

Sydney. These seemingly simple devices play a crucial role in

streamlining operations and optimizing workflows. In this blog, we'll explore

five ways industrial trolleys in

Syndey can boost efficiency in manufacturing industries.

Material Handling and

Transportation:

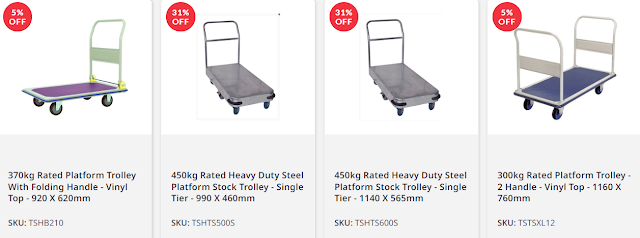

Efficient material handling is fundamental to the

smooth operation of any manufacturing facility. Sydney trolleys provide

a convenient solution for transporting raw materials, components, and finished

products throughout the production floor. By utilizing trolleys, workers can

quickly move heavy or bulky items from one workstation to another, reducing the

need for manual lifting and carrying. This not only minimizes the risk of

injuries but also saves valuable time that would otherwise be spent on

physically transporting goods. With the right trolley configurations, such as

shelves or compartments, materials can be organized and transported in an

orderly manner, further streamlining the process.

Assembly Line Support:

In assembly line manufacturing, where products

undergo a series of sequential steps, the timely delivery of components is

essential to maintaining a steady workflow. Industrial trolleys serve as

invaluable aids in this regard, facilitating the synchronized movement of parts

along the production line. By pre-loading trolleys with the necessary

components for each assembly stage, workers can access materials swiftly

without interrupting the production flow. This minimizes downtime, prevents

bottlenecks, and ensures that the assembly process remains efficient and

uninterrupted.

Tool and Equipment Mobility:

Manufacturing operations often require the use of

various tools and equipment, ranging from power drills to welding machines.

Industrial trolleys equipped with secure storage compartments provide a

convenient means of transporting these essential tools to wherever they are

needed on the shop floor. This eliminates the need for workers to make multiple

trips to retrieve equipment, saving time and effort. Additionally, designated tool

trolleys help keep workspaces organized by ensuring that tools are readily

accessible and properly stored when not in use, reducing the risk of misplaced

or lost items.

Inventory Management:

Maintaining accurate inventory levels is crucial for

preventing shortages and avoiding overstock situations that tie up valuable

resources. Industrial trolleys can play a vital role in inventory management by

facilitating the efficient movement of goods within the facility. By using

trolleys equipped with bins, trays, or adjustable shelving, workers can easily

transport, store, and organize inventory items throughout the warehouse or

production area. This simplifies stock replenishment processes, enables

real-time inventory tracking, and minimizes the likelihood of stockouts or

excess inventory buildup. With better inventory control, manufacturing

operations can operate more smoothly and cost-effectively.

Customization and

Adaptability:

One of the greatest strengths of industrial trolleys

lies in their versatility and adaptability to different manufacturing

environments and requirements. Trolleys can be customized with various

features, such as adjustable heights, interchangeable shelves, or specialized

attachments, to suit specific tasks or accommodate unique production needs.

This flexibility allows companies to optimize their workflows by tailoring

trolley configurations to match the demands of different processes or product

lines. Whether it's transporting delicate electronics or heavy machinery

components, there's a trolley solution that can be customized to meet the

challenge, ensuring maximum efficiency and productivity.

Thus, industrial trolleys

are indispensable assets that can significantly enhance efficiency in

manufacturing industries. From streamlining material handling and

transportation to supporting assembly line operations, these versatile devices

play a crucial role in optimizing workflows and maximizing productivity. By

investing in high-quality trolley solutions and leveraging their customization

capabilities, manufacturing facilities can unlock new levels of efficiency,

ultimately driving growth and success in an increasingly competitive market

landscape.

Comments

Post a Comment