Key Factors to Consider When Purchasing Industrial Trolleys

Industrial trolleys play a crucial role in the smooth operation of various businesses, from manufacturing plants to warehouses and distribution centers. These versatile tools help transport goods, materials, and equipment efficiently, reducing manual labor and improving productivity.

However, selecting the right industrial trolley for your specific needs is

not a one-size-fits-all decision. To make an informed choice for selecting the

best Industrial trolleys inSydney, you must consider several key factors that can impact your

operations and bottom line.

Load Capacity

The primary function of industrial trolleys is to transport loads from one

point to another. Therefore, the first and most crucial factor to consider is

the trolley's load capacity. The load capacity of a trolley is the maximum

weight it can safely carry. Exceeding this capacity can lead to accidents,

damage to goods, and wear and tear on the trolley itself. To determine the

appropriate load capacity for your needs, you should consider the heaviest

items you will regularly transport.

It's essential to have a safety margin when choosing a trolley's load

capacity. Overloading trolleys can result in accidents and injuries, so it's

wise to select a trolley with a load capacity that exceeds your maximum

expected load. Additionally, consider the distribution of weight, as uneven

loads can affect stability. Be sure to consult the manufacturer's

specifications to ensure you're selecting a trolley that can handle your

specific requirements.

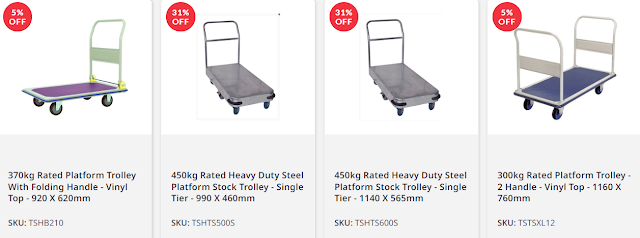

Trolley Type and Design

Industrial trolleys come in various types and designs, each suited to

specific applications. Common types include platform trolleys, hand trucks,

pallet jacks, and tilt carts. The choice of trolley type and design should

align with your operational needs and the nature of the items you need to

transport.

For instance, if you're dealing with bulky or irregularly shaped items, a

platform trolley with a flat, spacious surface may be ideal. On the other hand,

if you frequently need to move stacked goods or palletized loads, a pallet jack

or a forklift-compatible trolley might be more suitable. Moreover, consider

features such as wheel type (fixed or swivel), handle design, and

maneuverability, as they can significantly impact the ease of use and efficiency

of the trolley in your specific environment.

Wheel Configuration and Mobility

The wheels of an industrial trolley significantly impact its mobility and

maneuverability. Depending on your specific needs and workspace, you'll want to

pay attention to the wheel configuration and type. Common wheel configurations

include fixed wheels, swivel wheels, and a combination of both.

·

Fixed Wheels: Trolleys with fixed wheels move in a

straight line and are more stable when carrying heavy loads. They are ideal for

tasks that require precise positioning.

·

Swivel Wheels: Swivel wheels allow for greater

maneuverability, making it easier to navigate tight spaces and turn corners.

They are essential for trolleys that require frequent changes in direction.

·

Combination Wheels: Trolleys equipped with a combination

of fixed and swivel wheels offer a balance between stability and

maneuverability. They are versatile and suitable for various applications.

·

Consider the layout of your workspace, the need for

precise positioning, and the frequency of directional changes when choosing the

wheel configuration for your trolley.

Before making a purchase, it's advisable to consult with experts or

suppliers who specialize in industrial trolleys. They can provide valuable

insights and recommendations tailored to your specific requirements.

Comments

Post a Comment